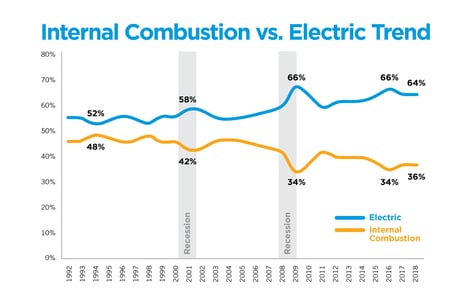

There was a major wave of electric conversion for forklifts beginning in the 2000s. A second phase of conversion is arriving. Propane is going away.

There was a time when this would have been unthinkable: in the past, propane-powered trucks and forklifts were the norm for a simple reason: they provided longer-lasting, more effective power than electric batteries could.

For the last 30 years, battery-powered forklift fleets have become the dominant offering in the market; more than 60%+ of forklifts sold now are electric versus propane/diesel. A second wave of conversions is coming, especially for heavier-duty, outdoor equipment. That’s because lead acid charging has improved and new tech has arrived, so the reasons for sticking with propane are few and far between.

Decades ago, this may have been a difficult decision, with pros and cons on both sides. But now, because of technological advances in electric power, it is not.

Today, when it comes to everything from productivity and performance to safety, sustainability, and savings, battery power is the best option for powering trucks and forklift fleets. Here’s why.

Four Reasons Propane is Going Away

Propane-fueled forklifts and trucks have been a mainstay for so long that it’s difficult to imagine a future where warehouses and plants exclusively utilize electric trucks and forklift fleets. But more and more companies are ditching propane, and that practice is only going to grow. Why? Here are the top 4 reasons:

1. Expense

Propane is more expensive than electric power. One simple reason for this is variability. While propane prices have come down recently, they tend to fluctuate, and there’s no telling when they’ll rise again.

Electric forklifts typically require less maintenance (though propane ones have improved), another reason cost has decreased. In fact, utilizing electric power significantly reduces cost of ownership over the lifetime of a forklift. So much so that a recent study by the Electric Power Research Institute found that $.040 worth of electricity did the same amount of work as $2.50 of propane. Ask your local power management partner to do an assessment and build out the business case today or call us for an assessment.

2. Efficiency

Another reason for propane’s high cost is inefficiency. Utilizing propane tanks means dealing not only with high labor costs but also with waste. Take this common scenario, for example: you use a propane tank about halfway, then swap it out during a break. The vendor comes and swaps in a new tank for the old one -- still half full of propane. You may have only gotten half a tank’s worth of propane, but you get charged for a full one.

Conversely, batteries have efficiency built in. With electric power, there’s no need to change fuel tanks or fill onboard tanks. And not only can a standard battery and charger now typically provide about 8 hours of power, but over the course of a three-shift workday, electric systems can be re-charged anytime that the battery is not in use -- whether that’s a lunch break, a bathroom break, or a brief break in production. These built-in opportunities make it easy to ensure batteries are running at or above 75% for three full shifts.

3. Environment and Safety

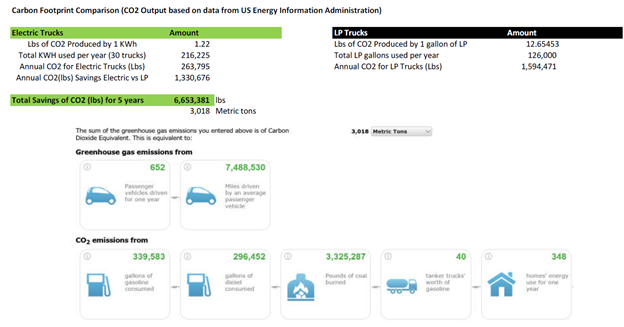

This one’s easy: electric power is the most environmentally sustainable fuel choice available. In addition to producing the lowest greenhouse gas of any available fuel source, the typical lead acid battery is 98% recyclable.

Utilizing electric forklifts makes it easier to achieve sustainability goals; it also means you’ll eliminate on-site carbon dioxide, carbon monoxide, and nitrous oxide.

And sounder environmental choices also mean a safer workplace environment: eliminating propane tanks means no fumes, which means a healthier work environment. Propane tanks can explode, causing serious injuries. An electric fleet never has oil or coolant spills, which means it never has accidents or injuries from these causes.

When you build out your business case, make sure you work with a power management partner that can also help you quantify your carbon reduction and sustainability impacts like this:

If you don’t have one, click here to talk to one of our solution engineers about an assessment.

4. Equal or Better Performance

In the past, when it came to power and performance, electric was regarded as lower-performing than propane—but that was before the transition from DC to AC power drives about 10 years ago. Ever since, electric forklifts have improved their power performance in side-by-side tests with propane. Today, electric power provides the exact or better level of power and performance as propane. That’s in part because new technologies like lithium, improved charging, and fuel cells have eliminated some of the limitations of traditional batteries.

That doesn’t mean your highest-use applications or heaviest outdoor equipment don’t present challenges or that you should convert in all situations. Find a power management partner that will do the homework and has a proven methodology for assessments, power system design and decision- making. You’ll want them to present you with the facts on performance (will it actually work?!), operational efficiency (will it be harder on my operators?), and cost and sustainability (what will my carbon impact be?). You’ll need those by every truck type down to every application—with an eye towards any growth you might experience. Armed with that data in black and white, you and your team will be equipped to make an informed decision with eyes wide open. Realize that there are always tradeoffs between cost and performance and safety and impact—just make sure you understand what those are before making a decision.

That said, in most cases today, electric power is now not only safer and more sustainable, but it’s also more cost-effective, more efficient, and just as powerful as propane. Most of the old excuses for not converting are now gone. That’s why in ten years, there will likely be very, very few propane forklifts left.

There are a lot of tough decisions in business. But if you’re facing a soon-to-expire forklift lease, the decision to switch to electric is no longer one of them.

Ryan Lynch

Ryan Lynch