Keeping your lead-acid forklift battery properly watered is essential for performance, safety, and longevity. At Concentric, we know that forklift battery maintenance goes beyond just charging—it’s about ensuring your battery has the right balance of water and electrolyte to keep operations running smoothly.

Why Water Matters in a Lead-Acid Battery

Water plays a critical role in the chemical reaction that powers a lead-acid battery. These batteries, also known as flooded or wet cell batteries, contain lead plates submerged in an electrolyte solution made of sulfuric acid and water. As the battery charges and discharges, water evaporates, lowering the electrolyte level. If the level drops too low and exposes the lead plates, it can cause permanent damage and reduce the battery’s ability to hold a charge.

What Happens When a Battery Runs Low on Water?

When the electrolyte level falls below the lead plates, the sulfate bonds can harden on the exposed surfaces. This crystallization reduces the battery’s efficiency and shortens its usable life. That’s why routine battery watering is crucial; it helps prevent damage and ensures consistent performance.

When Should You Add Water?

As a general rule, forklift batteries should be watered weekly. However, newer batteries may require less frequent watering, while older ones may need more attention. Always add water after charging, not before. Adding water before charging can cause overflow, which leads to the loss of sulfuric acid, which is a safety hazard that also shortens battery life.

The only exception is if the lead plates are already exposed. In that case, add just enough water to cover the plates before charging to prevent overheating. If your battery does overflow, contact a service technician immediately to inspect and restore safe operation.

⚠️ Never add sulfuric acid to a battery. It’s extremely dangerous and can damage both the battery and the person handling it.

How to Know When Your Battery Needs Water

Many forklift batteries come equipped with a battery water level indicator. Electrolyte level sensors use a simple color system:

- ✅ Green: Water level is good

- 🔴 Red: Battery needs water

- 🔴 Blinking Red: Water level has been low for 10+ days

If your battery doesn’t have a sensor, you can check manually using a flashlight. Look inside each cell. The fluid should be about ½ to ¾ inch above the lead plates. If it’s lower, it’s time to top off.

How to Safely Add Water to a Forklift Battery

Before performing any battery maintenance, always wear personal protective equipment (PPE). Goggles, gloves, and a face shield are recommended.

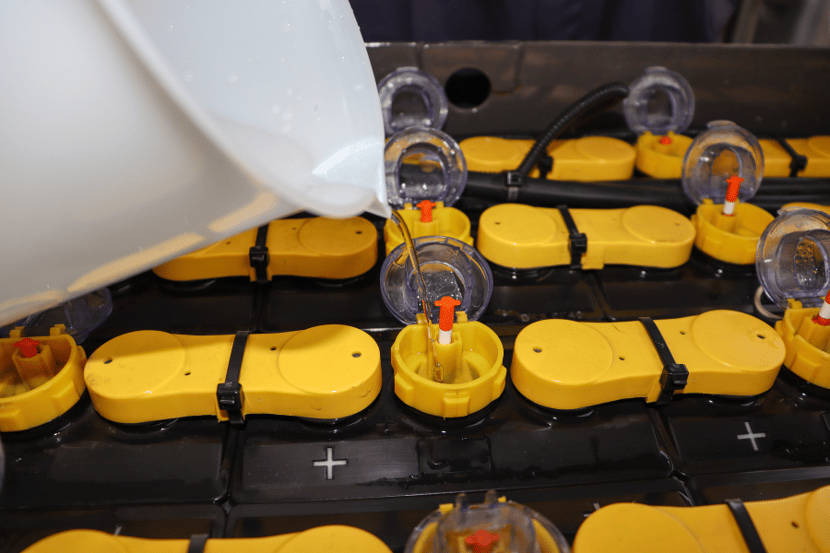

There are three common methods for watering forklift batteries:

- Battery Watering System

A network of hoses connects to each cell and automatically fills them to the correct level when connected to a water source. - Watering Gun

A technician manually fills each cell using a specialized nozzle that shuts off when the water reaches the proper level. - Gravity Feed System

A ceiling-mounted water tank feeds a hose used to fill each cell manually. A flashlight may be needed to check levels.

What Type of Water Should You Use?

Always use distilled water. Tap water, even if it looks clean, contains minerals that can damage the battery. Water from a softening system is even worse, as it adds more minerals. To ensure consistently high water quality, consider using a deionizer system, which removes harmful ions and impurities. If you're unsure, test the water with a pH strip—ideal water should measure between 5 and 7 on the pH scale.

Forklift Battery Maintenance Services from Concentric

At Concentric, we specialize in forklift battery repair and maintenance. Whether you need routine watering or emergency service, our expert technicians are ready to help and often within 24 hours. We’ll assess your battery, recommend a solution, and get to work quickly to minimize downtime.

Don’t let battery issues slow you down! Contact us for reliable maintenance solutions.