If you’re in charge of plant operations, chances are you’re being pressured to cut costs at the same time you’re expected to keep up with Amazon’s ever-increasing delivery speeds. Feels impossible, right?

If you’re in charge of plant operations, chances are you’re being pressured to cut costs at the same time you’re expected to keep up with Amazon’s ever-increasing delivery speeds. Feels impossible, right?

While we can’t magically grant you Amazon’s budget, we can help by explaining something that many of our clients view as the key to their success: maniacal focus on velocity versus speed.

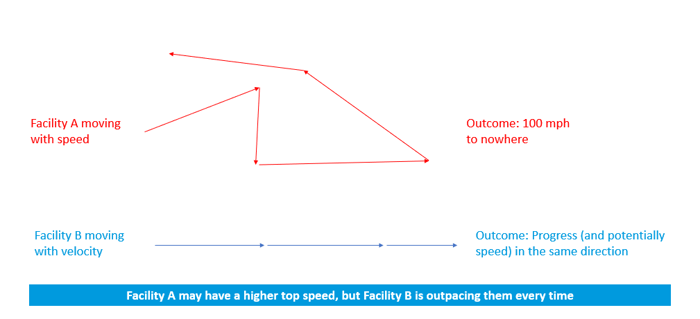

First, we need to understand and agree on the definition of the two terms. The biggest difference between speed and velocity is that while both deal with movement:

Speed - simply addresses the rate of movement while…

Velocity – factors in the direction of the movement, as well as the speed of the movement.

This is important when it comes to supply chain management because successful distribution and production operations are about improving in a specific direction every day. Building your team’s velocity is how you build predictability into your cost per pallet, on-time deliveries and continuous improvement.

Let’s take a closer look at what all this means.

Today’s Mandate for Operations

Focus in business today is often put on doing more, doing it better, and doing it with less. Companies are under tremendous pressure to keep up with competitors. Customers’ expectations are for increasingly faster, more efficient deliveries. In plant operations, the bulk of that load is put on forklifts, and it can be a struggle for plant operators to find the resources they need to keep up with customers’ expectations while also keeping up with demands to cut costs.

Speed vs. Velocity

It may help to think of velocity as business process alignment, like this quote suggests: “High speed is achieved by process automation. High velocity is achieved by process alignment: ensuring collaborative process progression, retaining process feedback, accumulating supporting documentation, combining request specific and supplementary information all for the benefit of the final executive decision.”

Think about it: you can’t make your forklifts move faster, but you can streamline your processes for precision and efficiency, ultimately resulting in greater output. Velocity equals process alignment, and process alignment maximizes your assets’ abilities to make money. Process alignment starts with everyone knowing their role and what is expected. It’s not just about an aligned process, it is also about having everyone on your team/facility on the same page. Aligned people and aligned processes will deliver velocity and continuous improvement.

The (Mistaken) Focus on Speed

Speed just means you’re moving fast. It doesn’t necessarily mean you’re moving in the right direction — that you’re learning and improving. Speed might help you maintain your business, but on its own, it won’t make your business better. Your business needs velocity — direction — to be effective.

3 Ways to Increase Velocity

Now that the difference between speed and velocity and the value velocity adds to speed are clear, how do you go about increasing velocity in supply chain management? Here are three places to start:

1. Identify sources of friction: Use data from internal systems, project management tools, etc. to identify weak spots in your processes and team. Take a closer look at those underperforming areas. Make observations, share it with your team for feedback, have discussions, and dig a little deeper to find out what can be improved. Keep in mind that your team can’t be strong in every area. Part of this self-evaluation will include considering outsourcing areas of weakness in order to amplify strengths.

2. Communicate purpose and goals: Review your internal goals with your team and evaluate how well they’re understood. Ask yourself if you and/or your teammates can clearly articulate your top 3 priorities. If you can’t or they aren’t written down, get them down on paper. Then, communicate them consistently. They say it takes teams ten times of hearing something before they’ll either remember or believe and execute on it! If you are putting in a new process and technology system, ask various team members questions like “Why are we doing this project?”, “Why does this team exist?” and “What are we trying to accomplish?” Getting back a variety of answers is a clear indicator that everyone is not moving in the same direction. To get your entire team to move with velocity, everyone needs to understand and be aligned on collective goals. As a leader, it’s your job to make sure everyone has the right information. If you are running the day to day operation, ask your teammates: “What is your day to day role and responsibility? What are the routines you have each day to make you effective? How do your teammates’ roles positively and negatively affect what you are trying to accomplish each day?”

3. Don’t fear change: It’s human nature to fear change, but the reality is that expectations, technology and business are evolving daily. Your business must become comfortable with change, and a good way to do that is to develop well-planned change management processes that mitigate issues and make transitions easier. Part of this process can involve adapting how your team thinks about change. Instead of something daunting and scary, it can become an exciting chance for growth and improvement. Help your team become comfortable with learning and changing.

The bottom line is this: Though people often confuse speed and velocity, only velocity will improve and grow your business. To gain velocity in your business, you must have everyone aligned with clear roles and responsibilities and outcomes continuously measured.

Sound like a lot of work? It is at first, but another way to tackle some of your core priorities is to partner with like-minded organizations to help you build velocity in areas where you don’t have expertise or don’t need to have expertise.

If your business involves plant operations and supply chain management, forklift power is a great example. It is an often-overlooked area that greatly benefits from a focus on velocity rather than reactive speed. At Concentric, we start every engagement with a month-long power assessment, so we base all strategic and tactical direction on real data.

If you’d like to hear more about our process, we’d be happy to have a conversation.

Ryan Lynch

Ryan Lynch